Macam-macam valve yg sering dijumpai di plant adalah sebagai berikut :

- Gate Valve, valve yg terdiri dari dinding yg mirip dg gerbang pagar. Pengoperasiannya adalah ditarik naik turun full dan tidak bisa digunakan setengah bukaan. Jadi aliran berhenti atau mengalir saja dan tidak bisa utk mengontrol besar kecilnya aliran

Keuntungan :

- Kapasitas aliran tinggi

- Biaya rendah

- Desain dan operasi sederhana

- Gesekan aliran thd valve sedikit

Kerugian :

- Sulit dalam mengontrol aliran karena saat aliran masih mengalir harus dihentikan scr tiba-tiba

- Kekuatan dari gate harus tinggi

- Posisi penggerak buka tutup yg terus menerus bisa menyebabkan erosi

- Hanya bisa digunakan utk buka full atau tutup full

"The kinds of valves often we know in plant such as :

1. Gate Valve, valve consist of wall similar with fence gate. Operation is pulled up - down full and can't be used half opening. So flow is off or on only and can't to control large small flowrate

Advantages :

- High flowrate capacity

- Low cost

- Simple design and operation

- Valve flow friction is slightly

Disadvantages :

- Difficult to contol flowrate because time flowrate still flowing must be stopped suddenly

- High of strength gate

- Position of handle on / off continue done can due to errosion

- Only can be used to full open or close"

|

| Gate Valve |

2. Plug valve, valve yg penghambatnya berbentuk silinder. Aplikasi utk fluida yg densitasnya besar

Keuntungan :

- Operasi cepat

- Kapasitas aliran besar

- Harga murah

- Kuat menahan fluida berat / lumpur

Kerugian :

- Bahan silinder harus kuat

Advantages :

- Quick operation

- Large flow capacity

- Low cost

- Resistance to hold weight fluid / sludge

- Material cylinder must be strong."

|

| Plug Valve |

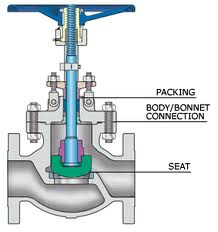

3. Globe Valve, disk yang bergerak tegak lurus sehingga saat diangkat naik fluida mengalir dan saat turun kran tertutup. Digunakan utk mengatur laju aliran fluida

Keuntungan :

- Akurat dalam kontrol aliran

- Kemampuan menutup baik

Kerugian :

- Pressure drop tinggi

- Harga mahal

"3. Globe Valve, disk moving vertical so if disk up fluid is flow and disk down mean close valve. Used to regulate flowrate fluid

Advantages :

Advantages :

- Accurate in flow control

- Good capability to close

- High pressure drop

- Expensive cost"

|

| Globe Valve |

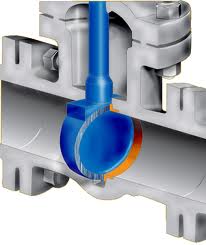

4. Ball Valve, valve yg dilengkapi bola yg berlubang sbg penghalangnya. Jadi saat posisi lubang sejajar aliran maka valve membuka dan saat posisi lubang tdk sejajar aliran maka kran menutup.

Keuntungan :

- Harga murah

- Kapasitas aliran tinggi

- Tidak membutuhkan pelumasan

- Pembersihan mudah

- Rendah kebocoran

- Bisa digunakan utk tekanan dan suhu tinggi

Kerugian :

- Sulit dalam pengembalian secara halus dari terbuka ke tertutup karena derasnya aliran fluida melewati lubang

Advantages :

- Low cost

- High flow capacity

- No lubricant

- Easy maintenance

- Low leakage

- Can be used for high pressure and temperature

- Expensive return smoothly from open to close due to high flowrate of fluid passing hole"

|

| Ball Valve |

5. Butterfly Valve, digunakan utk aliran fluida bertekanan rendah. Terdiri dari disk tipis yg ditengahnya terdapat sumbu putarnya

Keuntungan :

- Kapasitas aliran besar

- Perawatan dan harga murah

- Kompak dan ringan

Kerugian :

- Tidak bisa digunakan utk rate aliran tinggi

"5. Butterfly Valve, used for fluid with low pressure. Consist of slim disk with middle there is shaft rotate.

Advantages :- High flow capacity

- Low cost and maintenance

- Compact and light

- Can't be used for high flowrate"

|

| Butterfly Valve |

6. Diaphragm Valve, bisa digunakan utk mengatur laju aliran dan bisa digunakan utk on / off aliran. Efektif utk material kasar

Keuntungan :

- Harga murah

- Tahan penyumbatan dan korosi

- Tidak terjadi kebocoran

Kerugian :

- Umur diafragma tergantung pemakaian

"6. Diaphragm Valve, can be used to regulate flowrate and also used for on / off flowrate. Effective for rude material

Advantages :

- Low cost

- Resistance dirt and corrosion

- No leakage

- Diaphragm life is dependent application"

|

| Diaphragm Valve |

7. Pinch Valve, cocok digunakan utk fluida kasar

Keuntungan :

- Harga dan perawatan murah

- Tahan korosi dan abrasi

- Desain sederhana

Kerugian :

- Sulit dalam pengukuran

- Terbatas utk aplikasi kondisi vakum

Advantages :

- Low cost and maintenance

- Resistance corrosion and abbrasion

- Simple design

- Difficult measuring

- Limited vacuum application"

|

| Pinch Valve |

8. Check Valve, digunakan utk membuat aliran ke satu arah saja dan membuat aliran tidak bisa balik. Aplikasi biasanya pada sisi suction pompa sentrifugal

Keuntungan :

- Tahan terhadap benda kasar

- Turbulensi dan tekanan dlm valve rendah

Kerugian :

- Rate yang tinggi dapat membanting valve dan jika terus menerus penahannya bisa patah

Advantages :

- Resistance to rude material

- Low turbulence and pressure in the valve

- High flowrate can strike valve and if done continue can be broken"

|

| Check Valve |

9. Relief Valve dan Safety Valve, valve yg digunakan utk pengamanan alat dari bahaya, misalnya kelebihan tekanan dll. Relief Valve bekerja membuka secara perlahan dan menutup perlahan apabila kondisi normal, cocok utk fluida liquid. Safety valve bekerja membuka secara cepat dan langsung full buka dan kembali menutup dg cepat saat kondisi normal, cocok utk fluida gas.

Keuntungan :

- Desain gagal aman, jadi kalau alat tidak bekerja maka proses tetap aman

- Tidak memerlukan energi dari luar utk menggerakkan valve

"9. Relief Valve and safety Valve, valve is used to protect instrument from hazard, like excess pressure etc. Relief valve working slowly open if there is problem and slowly close if normal condition, good for liquid. Safety valve working quick open and direct full open and return close quickly if normal condition, good for gas.

Advantages :

- Save failure design, if instruments not working so procces is save

- No need external energy for moving valve"

|

| Relief and Safety Valve |

10. Control Valve, dilengkapi dg pegas jadi saat ada kondisi melebihi set point, pegas akan melar dan valve terbuka dan kondisi normal spring kembali

"10. Control Valve, completed spring with working if condition excess set point, spring will elastic and valve is open and if normal condition spring will return "

"10. Control Valve, completed spring with working if condition excess set point, spring will elastic and valve is open and if normal condition spring will return "

|

| Control Valve |

Kutip Artikel ini sebagai Referensi (Citation):

Feriyanto, Y.E. (2012). Macam-Macam Valve, Best Practice Experience in Power Plant. www.caesarvery.com. Surabaya

Referensi:

[1] Feriyanto, Y.E. (2012). Best Practice Experience in Power Plant. Surabaya

[2] Standar Handbook of Plant Engineering, Dressser Valve Divission : Stafford Texas

ARTIKEL TERKAIT :

1. Macam - Macam Pompa (Pump)

2. Macam - Macam Reaktor (Reactor)

3. Macam - Macam Kompresor (Compressor)

Previous

« Prev Post

« Prev Post

Next

Next Post »

Next Post »